-

Optyczne szkło kwarcowe

-

Obróbka szkła kwarcowego

-

Rurka ze szkła kwarcowego

-

Kwarcowa rurka kapilarna

-

Rurka ze szkła borokrzemianowego

-

Pręt ze szkła kwarcowego

-

Części zamienne do lasera

-

Cel rozpylania dwutlenku krzemu

-

Aparat kwarcowy

-

Płyta ze szkła kwarcowego

-

Niestandardowe części szklane

-

Niestandardowe części ceramiczne

-

Sprzęt do produkcji optycznej

-

Mobilna maszyna do produkcji szklanych pokryw

-

Optyczny przyrząd pomiarowy

-

kryształ optyczny

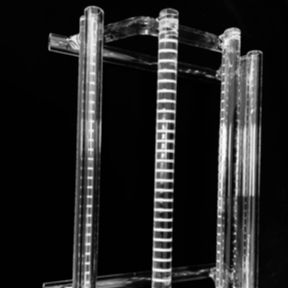

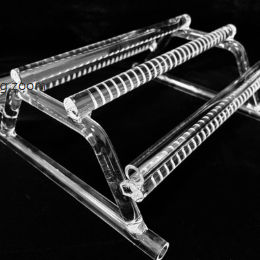

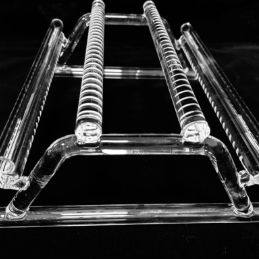

Customized Fused Quartz Wafer Boat for Solar Panel Manufacturing

Skontaktuj się ze mną, aby uzyskać bezpłatne próbki i kupony.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

W razie jakichkolwiek wątpliwości zapewniamy całodobową pomoc online.

x| Temperatura pracy | 1100°C | Powierzchnia | Jasne i przejrzyste |

|---|---|---|---|

| Kształt | Dostosowane | Siła zginania | 67 MPa |

| Podkreślić | customized fused quartz wafer boat,quartz wafer boat for solar panels,optical quartz glass wafer boat |

||

Customized Fused Quartz Wafer Boat for Solar Panel Manufacturing

A core carrying device specifically designed for high-precision manufacturing fields such as semiconductors, photovoltaics, and electronic components. Leveraging the excellent performance of quartz materials, it achieves safe loading, uniform heating, and pollution-free processing of precision workpieces, making it an indispensable key auxiliary equipment in high-end manufacturing processes.

Made of high-purity quartz material (purity ≥99.9%) through high-temperature melting and precision molding, it boasts three core characteristics:

① Exceptional high-temperature resistance, capable of stable operation in a high-temperature environment of 1200℃-1400℃ for a long time, with a short-term tolerance temperature of up to 1600℃;

② Superior chemical stability, resistant to corrosion by strong acids, alkalis, and various corrosive gases, without chemical reactions with workpieces, ensuring processing purity;

③ Excellent light transmittance, allowing heat sources to penetrate evenly, ensuring consistent heating of workpieces and improving processing accuracy;

④ Smooth and clean surface, precision polished without burrs or residual impurities, avoiding scratches or contamination of workpieces.

We are a high-tech enterprise with strong development capacity and general strength, delivering comprehensive solutions including R&D, glass processing, production, marketing and global trade. Our company specializes in the custom processing of various optical glasses, including glass capillary tubes/rods, shaped glass tubes/rods, laser cavity, quartz parts, quartz plates and quartz instrument etc. Products are widely used in semiconductor, communications, solar energy, electronics, optics, optical fiber, aerospace, military, chemical industry, coating, medical treatment and many other high-end industries.The company is located in China Shandong, has a large-scale production base, total area of 20, 000 square meters.

The company takes product quality as its tenet. Each product is strictly controlled from material selection, processing, inspection, packaging, transportation to after-sales service. With technological innovation as the driving force, a large-scale and systematic production model has been formed. The product sales have been spread all over the world, and are trusted by users in Asia, Europe, the United States, South Korea and India. It has established a high-quality product image and brand in the field of glass deep processing. Adhering to the service concept of the quality first and customer-oriented, through unremitting efforts and continuous improvement, We have created a good manufacturing platform of optical glass for customers.

![]()

![]()

![]()

![]()

![]()